To guarantee safe 3D printing without panic, focus on proper ventilation and careful resin handling. Use exhaust fans venting outside or air purifiers with activated carbon filters to disperse fumes effectively. Always wear PPE like nitrile gloves and goggles, and store resin properly in sealed containers away from heat and sunlight. Regularly maintain your ventilation system and stay aware of potential hazards—all essential steps to keep your workspace safe and stress-free. Discover more tips to stay safe during your print projects.

Key Takeaways

- Ensure proper ventilation with exhaust fans and air purifiers to safely disperse fumes during 3D printing.

- Wear appropriate PPE such as nitrile gloves, safety goggles, and masks to protect against resin exposure.

- Store resin in sealed, labeled containers away from heat and sunlight to prevent leaks and hazards.

- Regularly check and maintain ventilation systems and filters to keep air quality safe and effective.

- Follow safety protocols and disposal regulations to handle resin waste and prevent environmental contamination.

Why Proper Ventilation Is Essential for Safe 3D Printing

Have you ever considered what fumes and particles your 3D printer releases during operation? Poor ventilation can compromise air quality, leading to potential health risks. Without proper airflow, harmful fumes can accumulate, exposing you to irritants or toxins over time. That’s why adhering to safety protocols is essential. Ensuring your workspace has adequate ventilation systems helps disperse fumes quickly, maintaining a safe environment. Using exhaust fans or air purifiers can greatly reduce airborne particles and improve overall air quality. Proper ventilation systems are crucial for maintaining a safe and healthy 3D printing environment. Ventilation not only protects your respiratory health but also preserves the integrity of your workspace. Remember, good ventilation is a simple yet critical step to keep your 3D printing safe and enjoyable. Proper resin handling is equally important to prevent skin irritation and health issues. Prioritize it to avoid unnecessary hazards and breathe easier during your projects. Additionally, understanding the testing accuracy of your filtration and ventilation equipment can help ensure your safety measures are effective. Incorporating air quality monitoring devices can help you detect airborne contaminants early and adjust your safety measures accordingly.

Identifying Common Resin Fumes and Their Risks

Do you know which fumes are released when working with resin in 3D printing? When you cure resin, it emits a distinct resin odor, often indicating the release of volatile organic compounds (VOCs). These fumes can pose health risks through chemical exposure, especially with prolonged or repeated exposure. Common resin fumes include substances like formaldehyde, methyl methacrylate, and other VOCs, which can cause headaches, dizziness, or respiratory irritation. Some fumes are more hazardous than others, so recognizing their presence is essential. The presence of regional flavors and unique scent profiles can sometimes mask or mimic chemical odors, making it even more important to monitor fumes carefully. The chemical composition of these fumes varies depending on the resin type and curing process, influencing their toxicity. If you notice a strong resin odor during printing, it’s a sign to improve your ventilation or protective measures. Ignoring these fumes increases the risk of chemical exposure, which can impact your health over time. Proper ventilation and protective gear are vital to minimize health risks. Additionally, understanding the volatility of these compounds can help you take more effective safety precautions.

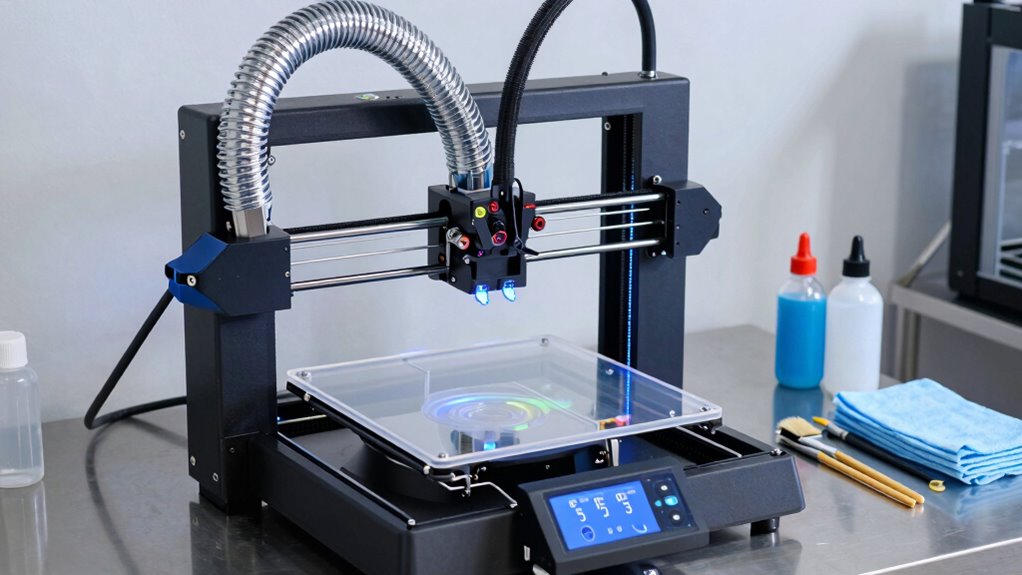

Setting Up a Ventilation System for Your 3D Printer

Proper ventilation is essential when working with resin in 3D printing to minimize exposure to harmful fumes. Start by placing an air filtration system near your printer to capture airborne particles and VOCs. Use a high-quality activated carbon filter for odor control, ensuring it effectively neutralizes strong resin smells. If possible, set up your printer in a well-ventilated space or designate a dedicated area with exhaust fans that vent outside. Keep the air filtration unit running during printing and for a while afterward to clear residual fumes. Regularly replace filters according to manufacturer instructions to maintain efficiency. Creating a controlled airflow not only reduces health risks but also keeps your workspace comfortable and odor-free. Proper setup makes safe resin printing achievable without panic. Additionally, proper handling techniques are crucial to prevent accidental spills and skin contact with resin. Ensuring good airflow management is an important part of creating a safe printing environment and reducing inhalation risks. Implementing ventilation best practices can further enhance safety and comfort in your workspace. Incorporating proper safety protocols can help prevent mishaps and ensure a safer working environment. Moreover, understanding the indoor air quality fundamentals can help you optimize your workspace conditions for safer printing.

Best Practices for Handling Resin Safely

Handling resin safely is vital to safeguard yourself from health risks and guarantee a smooth 3D printing process. Always wear gloves and protective eyewear when working with resin to avoid skin contact and eye irritation. Proper resin disposal is imperative; never pour leftover resin down the drain. Instead, store unused resin in sealed containers and follow local regulations for disposal. To prevent unpleasant odors, guarantee good odor control by working in well-ventilated areas and using activated carbon filters if possible. Clean spills immediately with paper towels and avoid inhaling fumes. Always read manufacturer instructions for safe handling and disposal. Being aware of resin toxicity and taking appropriate precautions can further reduce health risks. Implementing ventilation strategies significantly minimizes the inhalation of harmful fumes. Increasing air circulation in your workspace can further enhance safety and reduce fume buildup. Employing proper workspace design can also help contain fumes and improve overall safety. Additionally, using air purifiers with HEPA and activated carbon filters can greatly improve indoor air quality. By following these practices, you reduce exposure risk and maintain a safe, efficient workspace.

Choosing the Right Workspace and Storage Solutions

Choosing the right workspace and storage solutions is essential to maintaining a safe and efficient 3D printing environment. A well-organized workspace minimizes clutter and reduces the risk of accidental resin spills or contact. Invest in dedicated storage solutions like airtight containers for resin, cleaning supplies, and tools to keep everything contained and easily accessible. Use shelves or cabinets to maximize space and keep hazardous materials out of reach. Clear labeling of storage containers enhances workspace organization and helps you quickly identify materials and safety gear. Ensure your workspace is well-ventilated and free from distractions. Proper storage solutions not only improve safety but also streamline your printing process, making it easier to work efficiently while minimizing risks associated with resin handling. Incorporating AI-powered safety monitoring systems can further enhance workspace safety by providing real-time alerts and guidance. Additionally, understanding nail biology can help in maintaining personal safety by preventing skin contact with hazardous substances. Maintaining awareness of proper handling techniques is crucial to prevent accidental exposure and ensure a safer working environment. Regularly reviewing safety protocols can also help keep safety practices up to date and effective.

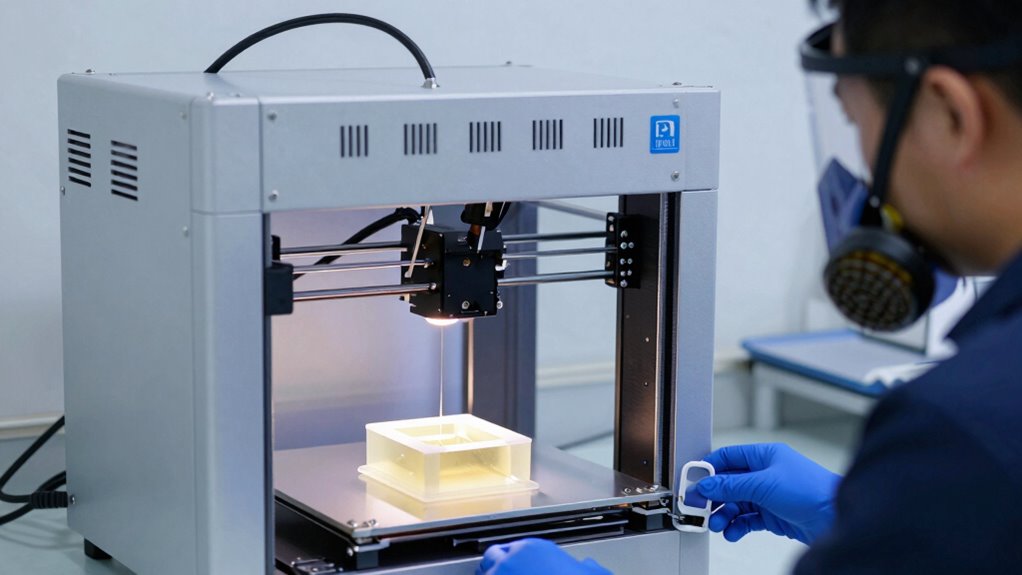

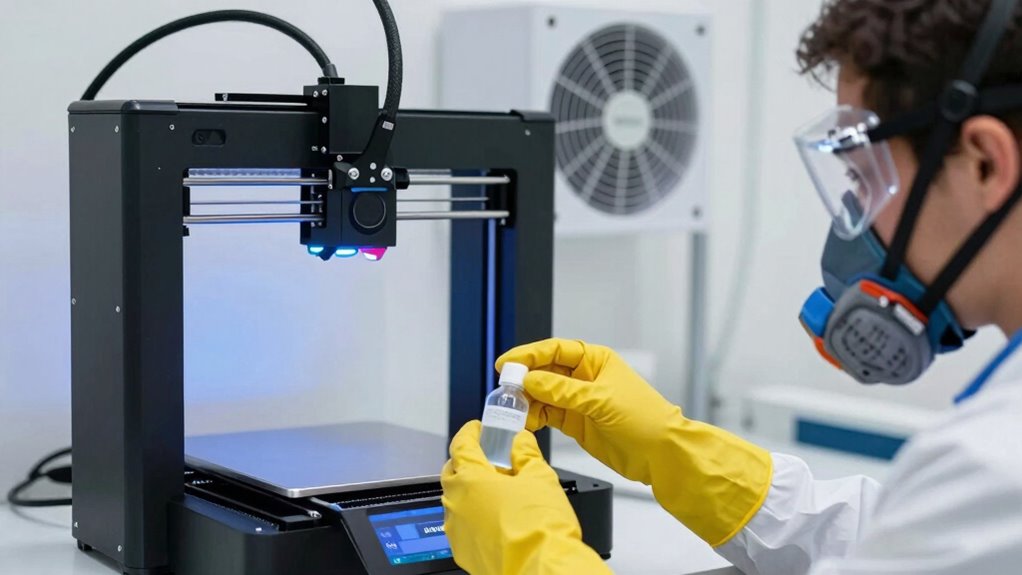

Using Personal Protective Equipment During Resin Printing

When working with resin printers, you need to wear the right personal protective equipment to stay safe. Choosing proper PPE, like gloves and masks, helps protect you from harmful chemicals and fumes. Remember to handle resin carefully and clean your equipment thoroughly to prevent accidents and contamination. Additionally, following proper maintenance procedures ensures your equipment remains safe and effective during use. In regions like the Northeast, where urban pursuits thrive, maintaining a safe workspace is especially important to enjoy your 3D printing hobbies responsibly.

Proper PPE Selection

Since resin printing involves working with potentially hazardous chemicals and UV exposure, selecting the appropriate personal protective equipment (PPE) is essential to guarantee your safety. When it comes to respirator selection, opt for a mask with a proper filtration system rated for chemical vapors, ensuring you don’t inhale harmful fumes. For glove types, choose nitrile gloves over latex, as they offer better chemical resistance and durability against resin exposure. Make sure gloves fit snugly to prevent leaks and tearing. Additionally, wear protective eyewear to shield your eyes from splashes and UV light. Proper PPE not only minimizes direct contact with hazardous substances but also creates a safer workspace, allowing you to focus on your print without unnecessary risks.

Handling Resin Safely

Handling resin safely during printing requires strict use of personal protective equipment to prevent skin contact, inhalation of fumes, and eye exposure. Always wear gloves compatible with resin, such as nitrile, to avoid skin irritation. Use safety goggles to protect your eyes from splashes and fumes. Verify proper ventilation to minimize inhalation risks. When finished, dispose of resin waste properly, following local regulations for resin disposal to prevent environmental contamination. Confirm resin compatibility before mixing or pouring to avoid dangerous reactions. Keep resin containers sealed tightly when not in use, and handle spills immediately with appropriate PPE. This careful approach reduces health risks and ensures a safe printing environment, making resin handling safer and more manageable.

Cleaning and Storage

Ever wondered how to keep your resin printer workspace safe during cleaning and storage? Proper resin storage is essential to prevent spills and accidental exposure. Always wear gloves, goggles, and a mask during cleaning routines to avoid skin contact and inhalation of fumes. When cleaning your resin printer, use lint-free cloths and appropriate cleaning solutions, handling resins carefully to avoid contamination. After cleaning, store unused resin in airtight, clearly labeled containers away from heat and sunlight. Ensure that cured resin parts are stored safely to prevent accidental contact. Regularly check your storage areas for leaks or spills, and dispose of waste materials according to safety guidelines. Following these steps helps protect you and maintains a safe, organized workspace.

Cleaning and Maintaining Ventilation Equipment Effectively

To keep your ventilation system working safely, you need to replace filters regularly and check that everything is functioning properly. Neglecting these steps can lead to poor air quality and potential health risks. Make it a habit to inspect and maintain your ventilation equipment consistently.

Regular Filter Replacement

Regular filter replacement is essential for maintaining effective ventilation when using a 3D printer. Fresh filters ensure ideal air quality by capturing harmful fumes and particles. Over time, filters clog and lose efficiency, reducing your ventilation system’s ability to protect you. Check your manufacturer’s guidelines for recommended replacement intervals, usually every 3 to 6 months. Regularly replacing filters prevents buildup that can compromise safety and air quality.

| Filter Type | Replacement Frequency |

|---|---|

| HEPA Filters | Every 6 months |

| Activated Carbon | Every 3-4 months |

| Pre-filters | Monthly or as needed |

| Particulates | When visibly dirty |

| Odor Filters | Every 3 months |

Sticking to these schedules keeps your workspace safe and your air clean.

Proper Ventilation Checks

Maintaining your ventilation system is essential for guaranteeing safe air quality when operating a 3D printer. Regularly check your ventilation equipment to assure proper air circulation, which helps remove fumes and reduce toxins effectively. Clean filters and vents frequently to prevent blockages that can compromise toxin reduction. Inspect fans and ductwork for dust buildup or damage, replacing parts as needed. Confirm that the exhaust system is functioning correctly, with airflow directed outside or into a filtration unit. Consistent maintenance guarantees ideal airflow, minimizing airborne hazards. By keeping your ventilation system in top condition, you ensure that fumes and particles are effectively vented, creating a safer environment and protecting your health during printing sessions.

Troubleshooting Ventilation and Resin Handling Issues

If ventilation isn’t effective, fumes from resins can build up quickly, posing health risks and affecting print quality. To troubleshoot, first check that your exhaust system is working properly and clear of obstructions. Ensure your workspace has adequate dust mitigation measures to capture airborne particles and fumes. If you notice persistent noise, inspect fans and ductwork for loose parts or blockages, which can hinder airflow. Proper maintenance of filters and vents helps keep fumes at bay. When resin handling issues arise, verify that containers are sealed tightly and stored in well-ventilated areas. Regularly clean your workspace to reduce dust and resin residue, which can interfere with ventilation. Addressing these issues promptly ensures safer, quieter printing and better print outcomes.

How to Educate Yourself and Others on 3D Printer Safety

Educating yourself and others about 3D printer safety is essential for preventing accidents and ensuring a safe printing environment. Start by understanding proper resin disposal methods to avoid environmental harm and health risks. Share this knowledge with anyone who uses or maintains the printer. Additionally, emphasize the importance of regular printer calibration to ensure accurate prints and reduce safety hazards caused by misaligned components. Encourage open communication about safety concerns, and provide clear instructions on handling resin, cleaning equipment, and venting properly. Keep safety guidelines visible near the workspace. By staying informed and proactive, you can create a safer 3D printing environment for everyone involved, minimizing risks and promoting responsible use.

Simple Tips to Keep Your 3D Printing Space Safe and Panic-Free

To keep your 3D printing space safe and calm, start with proper ventilation to clear out fumes and particles. Handle resins carefully to prevent skin irritation or accidents, and always have an emergency plan in place. These simple steps will help you stay prepared and keep your workspace worry-free.

Proper Ventilation Practices

Ensuring proper ventilation is essential for maintaining a safe and comfortable 3D printing environment. Good airflow helps improve air quality by dispersing fumes and particles generated during printing. To optimize airflow, position your printer near a vent or open window, and consider using a fan to direct fumes outside. Avoid blocking vents or creating stagnant air pockets that can trap harmful vapors. Regularly clean air filters and ensure ventilation systems are functioning correctly. Keep your workspace well-ventilated throughout the printing process, especially when working with resin or other materials that produce fumes. Proper ventilation not only reduces health risks but also helps maintain a fresh, comfortable environment, allowing you to focus on your project without panic or worry.

Safe Resin Handling

Wondering how to handle resin safely during your 3D printing projects? Start with proper resin disposal by never pouring leftover resin down the drain. Instead, store unused resin in sealed containers and follow local regulations for disposal. Always wear gloves and eye protection when handling resin to prevent skin and eye contact. Good odor management is key—use well-ventilated spaces or air purifiers to minimize fumes and odors. After printing, clean your workspace thoroughly to remove any resin spills or drips. Keep resin containers tightly sealed when not in use. Regularly check for leaks or cracks in bottles, and store resin away from heat or direct sunlight. These simple tips help keep your workspace safe, odor-free, and panic-free.

Emergency Response Planning

Having a clear emergency response plan is vital for maintaining safety during your 3D printing projects. You should regularly practice emergency drills to guarantee you know how to react quickly if a fire, chemical spill, or other incident occurs. Designate exits and keep safety signage visible, so everyone in your space knows the nearest escape routes and safety procedures. Make sure all team members understand the plan and have access to emergency contacts. Keep a well-stocked first aid kit nearby and verify fire extinguishers are in working order. Having these protocols in place not only minimizes panic but also helps you respond efficiently, protecting yourself and others from harm during unexpected incidents.

Frequently Asked Questions

How Often Should I Replace or Clean My Ventilation Filters?

You should replace or clean your ventilation filters every 3 to 6 months, depending on usage and filter type. Regular filter maintenance is vital to guarantee optimal airflow and safety. Keep an eye on the ventilation lifespan; if you notice reduced airflow or increased odors, it’s time for a replacement or cleaning. Proper upkeep helps maintain a safe working environment and prolongs your ventilation system’s effectiveness.

What Are the Signs of Resin Exposure or Poisoning?

A warning sign is when you notice respiratory issues, skin irritation, or headaches—think of it as a red flag waving. Resin poisoning or exposure symptoms include coughing, dizziness, skin rashes, or eye irritation. If you experience any of these, stop using the resin, improve ventilation, and seek medical advice. Staying alert helps you catch hazards early, keeping your workspace safe and your health protected.

Can I Use DIY or Homemade Ventilation Solutions Safely?

You can use DIY safety and homemade solutions for ventilation, but you need to be cautious. Confirm your homemade system has proper airflow, filters out harmful fumes, and is made from non-toxic materials. Always test your setup thoroughly before relying on it, and avoid cutting corners that could compromise safety. Remember, effective ventilation reduces resin exposure risks, so prioritize air quality and consider consulting safety guidelines or professionals to improve your homemade solution.

Are There Specific Brands of PPE Recommended for Resin Handling?

Yes, there are specific brands recommended for resin-specific PPE. Look for trusted brands like 3M, Honeywell, and Jackson Safety, which offer gloves, masks, and eye protection designed for chemical handling. These brands meet safety standards and provide reliable barriers against resin exposure. Always choose PPE labeled for chemical or resin use, and verify proper fit and usage to maximize safety during handling and curing processes.

How Can I Monitor Air Quality in My 3D Printing Space?

To monitor air quality in your 3D printing space, you can use air quality sensors that detect volatile organic compounds (VOCs) and other contaminants. These sensors provide real-time data so you can adjust ventilation as needed. Additionally, consider air purifier options with HEPA and activated carbon filters, which help remove fumes and particles. Regularly checking sensor readings and maintaining your air purifier keeps your workspace safe and well-ventilated.

Conclusion

Remember, safety isn’t just a precaution—it’s a priority. By properly ventilating your workspace, handling resins carefully, and staying informed, you can enjoy 3D printing without panic. As the saying goes, “A stitch in time saves nine.” Taking small, consistent steps now guarantees your projects stay smooth and safe in the long run. Stay vigilant, stay educated, and keep your environment secure for worry-free printing adventures.